Site 21 - King Street, Longton, ST3 1EZ

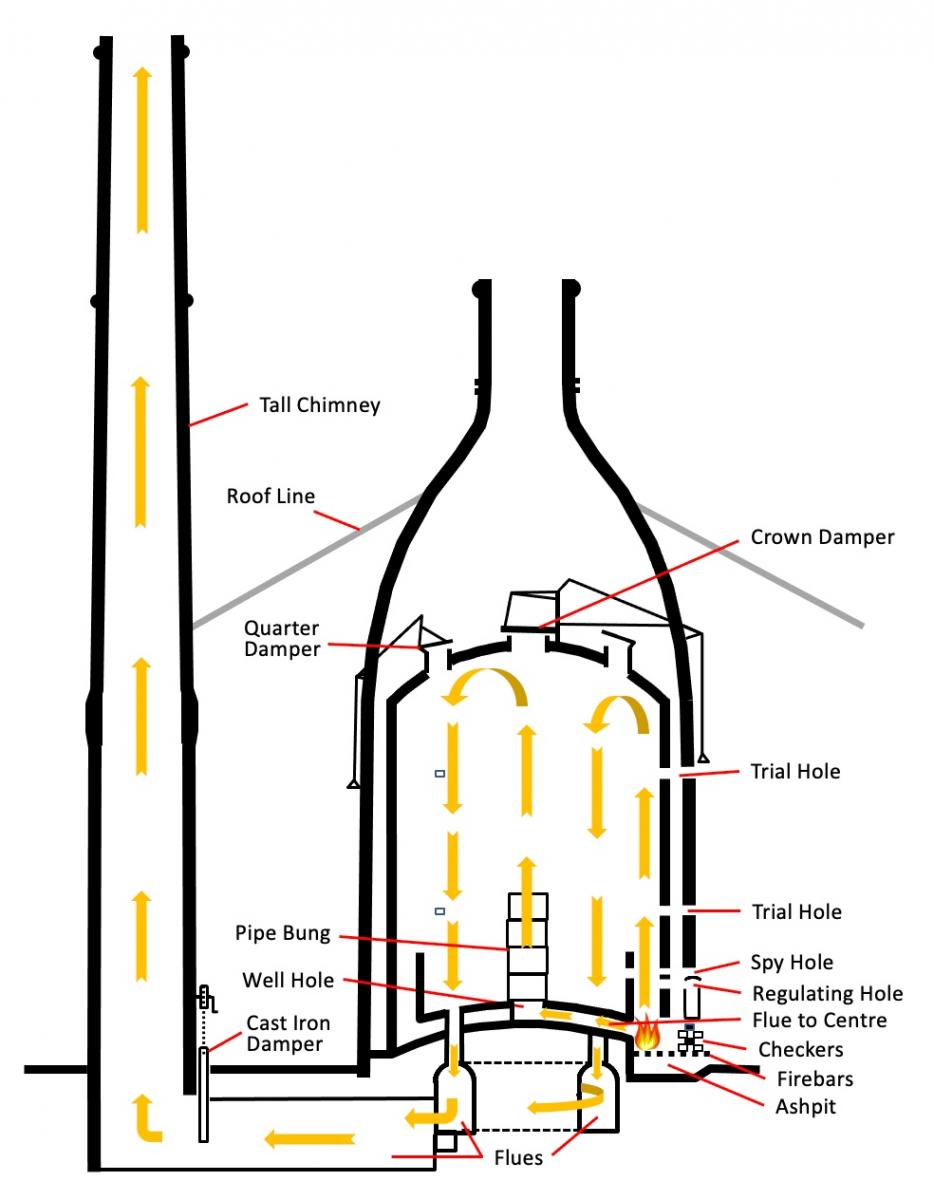

Type: Downdraught Bottle Ovens, Skeleton Type. A pair of downdraught ovens which operated with the help of the attendant chimney.

Date: The enclosing building is first shown on the 1900 OS map.

Listing: II and within the Longton Conservation Area

Past Use: Pottery factory established by Thomas Forester in 1879 on the site of an earlier works.

Phoenix Works, 500 King Street was built in 1881 by Thomas Forester (see Wikipedia: Thomas Forester & Sons) - to satisfy the tremendous demand for Majolica both at home and abroad. To find out more information on the history and pottery produced by Thomas Forester visit our website thomasforester.com. Thomas died in 1907 but the business was successfully carried on by his descendants until the clean air act of 1956 which prevented the use of the enormous coal fired bottle ovens (two of which still remain on the site to this day). Foresters finally ceased production in 1959. The complete history of the company and the works is documented in a book called “A Victorian Pottery, Thos Foresters’ The Forgotten Giant” by Peter Beckett.

Current Use: Office space and retail space and café.

The two remaining bottle ovens on site (there were originally six) were previously believed to be updraught ovens. But it has recently emerged they are examples of the much more unusual downdraught variety. Tunnels have also been unearthed that once connected the vents to an adjacent 90ft chimney. Downdraught ovens first appeared in the Potteries in the second half of the 19th century and offered a more efficient way of firing pottery. Unlike their updraught counterparts, they recirculated heat within their firing chambers, ensuring that wares were exposed to heat for a longer period. The format of the ovens, flues and adjacent chimney is a unique example of this type of technology within the city.